Forged steel, mechanical qualities preserved

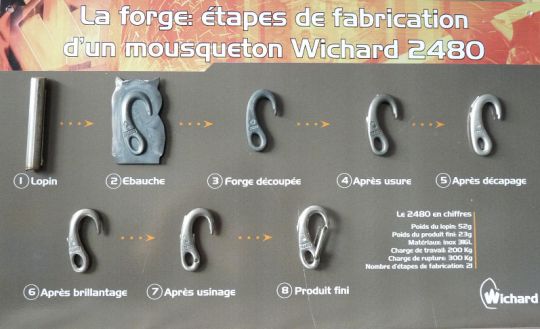

Wichard has been forging steel since 1919. From its democratized shackle ranges in the 1960s to the current quick release snap hooks, the company has remained faithful to this process and its technical and mechanical advantages. "We start from stainless steel coils or bars that are cut into pieces, small cylindrical parts. They are then heated in gas or induction furnaces, before being placed in a press to obtain the relief of the final part. The advantage over foundries where the metal is heated to a liquid state is that the orientation of the material structure remains homogeneous, with better mechanical characteristics. There is also no risk of incrustation of impurities in the core of the metal," explains Eric Butreau de Wichard.

The resulting part, called the blank, is then cut to separate the excess material for recycling. After several phases of mechanical and chemical treatment, the part takes its final external appearance. It can be machined if necessary, then assembled with other elements. "Mechanical tests are performed at the breaking load for all batches of parts for boating. The advantage of forged parts is their better fatigue strength compared to foundry. What we don't want in yachting is a sudden break-up," Eric Butreau argues.

A stainless steel grade for each use

Wichard mainly works with stainless steel or stainless steel, an appellation that includes alloys containing at least 12% chromium and nickel. Chromium gives the material its corrosion resistance qualities. There are 3 main families used in boating:

- austenitic products, the best known of which is 316 L stainless steel. Non-magnetic, its corrosion resistance is very good, but its mechanical properties are average. This makes it very suitable for exposed applications such as shackles, especially on anchor chains.

- martensitics, including 17.4PH, called HR at Wichard. Mechanical strength is greatly improved for medium corrosion resistance. The use of HR stainless steel parts such as swivels is strongly discouraged in the case of prolonged immersion (e. g. wetting lines).

- austeno-ferritic, duplex type. They offer both the mechanical strength of HR stainless steel and the corrosion resistance of 316L. Their use is growing, but they require the creation of new tools that are gradually being implemented.

Wichard buys its raw materials in France and Europe and controls the metallurgical composition of its stainless steels. The company also produces forged titanium parts, particularly for offshore racing in search of weight savings. These titanium parts also offer high corrosion resistance.

Capacity of custom-made nautical parts

The total control of the process, including the in-house manufacture of tools, allows Wichard to offer tailor-made parts to all its industrial and nautical customers, who go beyond standard expectations. The boat builder or equipment manufacturer consults on the basis of existing plans or specifications for use.