Recycling composites in boatbuilding has long been a dead end. Fiberglass-reinforced polyester hulls, which have dominated production since the 1960s, are very difficult to deconstruct, let alone recycle. But an industry is beginning to take shape. And it's being spearheaded by two well-identified players: Guillaume Perben, founder of Composite Recycling, and Erwan Faoucher, Innovation Director of the Beneteau Group.

In this video, the two antagonists together present the complete process that now makes it possible to recycle composite materials from manufacturing offcuts.

A well-known problem, but long without an industrial solution

Polyester and fiberglass are ubiquitous in yacht building. Resistant, inexpensive and easy to work with, these materials meet the economic and technical constraints of boatyards.

But their end-of-life poses a real problem. Thermoset composites are difficult to separate, cannot be recycled, and often end up in landfill sites after dismantling. The marine industry could no longer ignore this limitation, at a time when environmental issues are becoming central to both manufacturers and boaters.

A clear objective: to recover production offcuts in a closed loop

Rather than wait several decades to test recyclability on boats at the end of their life, the Beneteau group has chosen to start with a more controlled flow: scraps from the manufacturing process. Around 10% to 15% of the material used in the manufacture of a hull is lost: resin, reinforcements, cut-outs for portholes or hatches...

These scraps, which used to end up in the skip or in energy recovery, are now recovered and reprocessed into raw materials for use in new hulls.

A pyrolyzer at the heart of the separation process

The key to the system is a pyrolyzer developed by Composite Recycling, a Swiss start-up founded by Guillaume Perben. This equipment heats composite materials to around 400°C, a temperature sufficient to :

- decompose the thermoplastic resin,

- free the glass fibers, without burning them.

Two products are then recovered:

- a pyrolysis oil derived from the resin, which can be reprocessed by Arkema into new resin,

- glass fibers, which can be remelted and rethreaded.

"L he process recovers materials with the same mechanical properties as their original state "says Erwan Faoucher in the video.

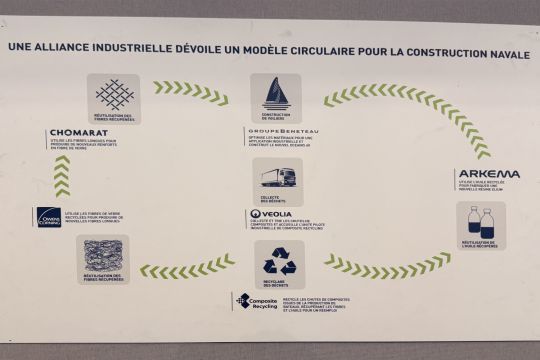

An industrial chain set up with several partners

The project's success is based on an alliance of specialized manufacturers:

- Arkema recovers pyrolysis oil to produce a new Elium resin, recyclable and compatible with current processes,

- Owens Corning remelts fibers to make them spinnable,

- Chomarat transforms them into technical fabrics, adapted to the mechanical constraints of the boat.

At the end of the chain, Beneteau reuses these materials in the manufacture of new units.

First concrete applications scheduled for 2026

The project is about to enter its first phase of industrial-scale application, with the integration of these recycled materials into the construction of a Lagoon 82, a 25-meter catamaran. This boat will serve as a demonstrator to test the integration of recycled fibers with another resin (not Elium), in order to separate the variables.

A second boat, this time made with Elium resin and combined recycled fibers, has also been announced for 2026. Its name has not yet been announced.

Towards an extension to end-of-life boats?

Reusing offcuts is a first step. The medium-term goal is to be able to apply the same processing chain to used boats. But this poses several problems:

- the quality of materials is highly variable,

- composites are old, sometimes without traceability,

- the cost of treatment remains high.

" We're on the right track, but we still need to establish a viable business model for processing old hulls "admits Guillaume Perben.

The sector could open up to other shipyards (other than those of the Bénéteau Group), as the solutions developed are modular: some could adopt only the resin, others only the fiber treatment.

Conclusion

For decades, composite recycling has been a black spot in the shipbuilding industry. The alliance between Beneteau and Composite Recycling is a game-changer: for the first time, a complete recycling loop for composite scraps is operational. It's a tall order, but the first boats to come out of this chain are expected as early as 2026. This will mark the start of a structural change in industrial practices in the marine industry.

/

/