The widespread use of carbon fiber in the construction of ocean-going yachts is accompanied by a significant ecological footprint. Aware of this challenge, Grand Large Yachting has entered into a partnership with Nova Carbon to gradually introduce recycled fibers into its processes. This marks an important step for the marine industry, where the transition to circular materials is still in its infancy.

Grand Large Yachting, a frontline shipyard

Founded in 2003, Grand Large Yachting brings together several French shipyards specializing in ocean-going yachts, from RM monohulls to Outremer catamarans. The growing proportion of carbon in their units, whether for masts, appendages or structures, has forced the group to rethink its sourcing. By setting up an in-house collection and recycling system for its carbon waste, the shipyard has taken a step towards more circular management of its materials.

A strategy for replacing virgin carbon

The Group plans to substitute part of the virgin carbon fiber with recycled fibers from its own production process. This approach not only limits the landfilling of composite waste, but also reduces dependence on imported virgin carbon. The first applications concern non-critical parts, in order to validate mechanical properties and production consistency.

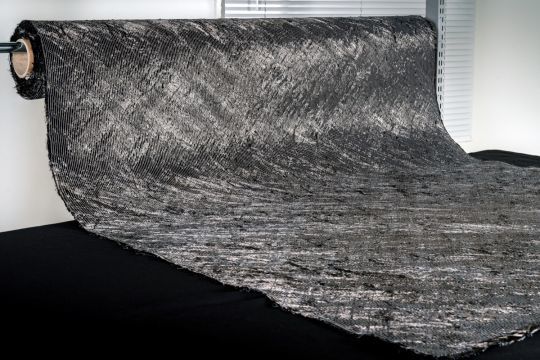

Nova Carbon's processes

Nova Carbon's technology is based on realigning the collected fibers to maintain a mechanical strength close to that of new fiber. This know-how makes it possible to offer a material that can be reintegrated into naval laminates, subject to rigorous quality controls. For Grand Large Yachting, the challenge is to validate these materials in its own shipyards and, eventually, to extend their use to mass production.

Towards distribution within the industry

The shipyard's ambition goes beyond its own needs. By making its carbon waste available and exploring its reuse, Grand Large Yachting hopes to involve its subcontractors and industrial partners. This collaborative approach could encourage the emergence of a French recycled carbon industry, which is still relatively unstructured in the nautical sector.

Standards and industry acceptance

The success of this initiative will depend on the recognition of recycled fibers by architects, engineers and certification bodies. Mechanical properties must be guaranteed at the same level as those of virgin fiber. Batch traceability and process standardization are essential conditions for convincing professionals of the validity of this approach.

/

/