Making the flying boat more accessible

Benoit Marie is one of the French references in the series of moth, small hydrofoil sailing boats, pioneers of flying boats. However, he readily acknowledges the difficulty of access to these practices for the general public boater. He has therefore decided, through the Vinilab project, to work to open up flying to a wider spectrum. "This project is the synthesis of several ideas. Hydrofoil boats are exceptional in terms of performance and sensations, but they are very constraining. If the boat is out of tune, it is complicated to fly. And tuning is complicated for a beginner. I realised this when I lent my moth to someone from Airbus who had helped me with my project. He knew how to sail, but he wouldn't have been able to make his first board alone and return home. These boats are not very accessible and expensive. The idea is to make them technically and financially accessible" summarizes Benoît Marie.

An affordable platform for developing foils

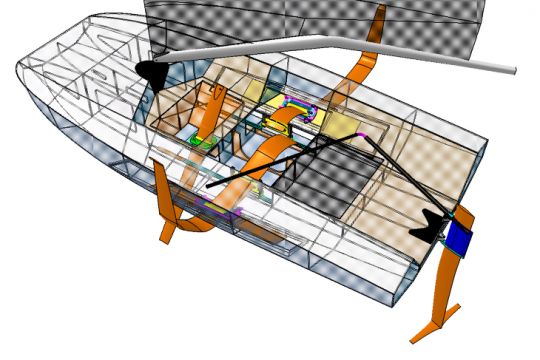

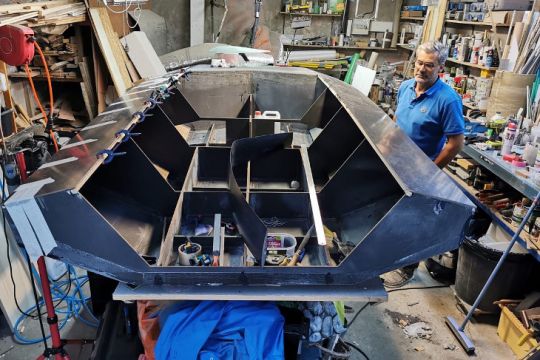

The cost of developing a foil is the first obstacle to their democratization. To lift it, the engineer has therefore thought of an affordable tool for the boat designers of today and tomorrow. "Currently the development of foils is mainly done for IMOCA, Ultim or America's Cup boats and costs several hundred thousand euros. If you want to do it in a Mini, it costs several tens of thousands of euros, which is still expensive. Simulators exist, but a year-round licence costs up to 80,000 euros. There is a market for the less fortunate who want to test foils before building. So we thought of the smallest possible boat, where everything is adjustable with strings. The foil shaft has five degrees of freedom. The starboard and port foils are different. The daggerboard is adjustable in tilt and angulation. The boat is versatile," explains the skipper.

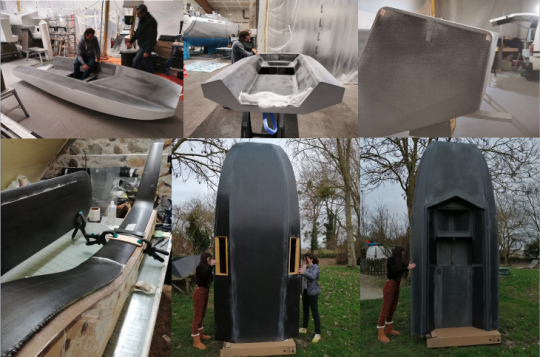

A boat made of salvaged materials

To combine Vinilab with his ecological conscience, Benoît Marie wanted to use as many reusable products as possible. "The boat is 90% overcycling. Everything, except the fittings and the resin for rework. The carbon of the hull is made with outdated aeronautical prepreg according to their criteria. The rigging is that of a previous generation international moth. The foils were donated by a Class A shipyard, corresponding to an older generation.

Preparing tomorrow's foil boat

Initially, the Vinilab will allow the acquisition of data for scientific articles and the validation of numerical models. It will serve as a test platform for customers for the development of foils, but also for equipment manufacturers in connection with the field. "To validate its automatic pilot, a supplier must adapt to the schedule of large race projects, where it can do so in an affordable way and in autonomy" illustrates Benoît Marie.

In a second step, Vinilab will be used as a support to think about a small accessible foil boat. "I've always dreamed of a cruising moth," he concludes.