The genesis of the project

It was by participating in the GC32 circuit regattas that Bertrand Castelnerac, one of the founders, came up with the idea of creating SEAir. "The coach couldn't keep up with the boats, forced to wait in the wind, on a semi-rigid, hitting boat." begins Bertrand.

In the area where the foil is becoming more democratic and industrial projects are born, the founder of the Breton company decided to set up a Mini foil project in the field of sailing. Finally, the idea was abandoned and Bertrand turned to his shareholders to propose another project. He then explained the problems encountered by the semi-rigid escorts of the GC32s and his idea to solve them: foils specially adapted for motor boats.

"The idea is well received since 80% of the French fleet is composed of motor boats, of which 80% are semi-rigid" supports Bertrand.

Bertrand Castelnerac, one of the founders of SEAir © Bateaux.com

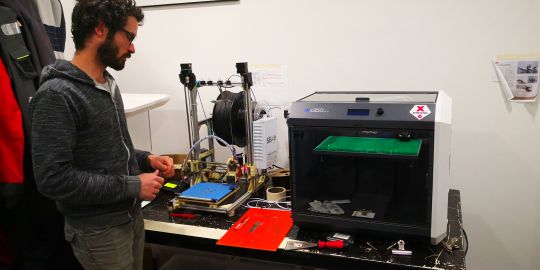

In 2006, patents were filed and the company acquired mechanical, engineering, foil control and 3D manufacturing services. "We make kit foils based on plastic or carbon parts printed in 3D."

This is how SEAir launched its first hydrofoil boat. On a Zodiac semi-rigid boat, he installs these large daggerboards that allow the boat to be supported. "These are non-flying foils, a kind of non-archimedian drift."

This is a turning point for the motorboat sector and more particularly for the semi-rigid sector. And if other projects continue to emerge, SEAir is the precursor of the flying boat.

"The boat's normal sailing position is above the water. It's graceful and you can feel all the movements." exclaims the founder of SeAir.

The 3D printer © Bateaux.com

The foil to free itself from the waves

"In the motorboat, we have phenomena to consider that are different from those of sailing." explains Bertrand. Thus, reaching maximum speed is not the objective. "It is believed that the foil allows extreme speeds to be reached. We could of course, but on the one hand that's not the objective and on the other hand it could be dangerous. In practice, 30 knots are easily reached in flight, but the optimization of flight at medium speeds is sought."

The idea of the SEAir foil is to reduce the effect of wave height and to be able to sail even when there is a swell. Because once the boat is lifted, it slides on the water and completely frees itself from the sea state. And if we would tend to ease off when the waves arrive, on the contrary, we should avoid slowing down when the wave train arrives.

"The foil breaks a lot of apriori. Apart from the idea of speed and waves, people think that the boat does not turn. But it runs flat without any problem." supports Bertrand.

Foil template © Bateaux.com

A necessary flight adjustment

To operate, the semi-rigid hydrofoil requires adjustments. Indeed, it is not enough to put the throttle on to take off . "It's a pretty basic foil design, which requires trim settings. The pitch must be adjusted for more direct reactions."

With its foils, the boat takes a little more drift and lateral movement, which replaces longitudinal movement.

If at the launch of its foil technology, SEAir wants to make the foil "easy" and accessible to everyone by democratizing it, today, the demand is moving towards a high-end market.

The foils waiting to be installed © Bateaux.com

A range in development

If for the moment SEAir was working with Zodiac - the boats are sold to the Breton company, which then prepare them in its workshops - other manufacturers are interested in this technology. This is the case of Bénéteau, which has also developed a prototype hydrofoil motor boat in collaboration with the company, or of Sillinger or Highfield interested in equipping their boats with this flight system.

A semi-rigid boat equipped with foils © Bateaux.com

When will there be a boat SEAir??

"What is expensive are the shell molds. You have to do mass production to make it profitable." explains Bertrand. "If we created our own boat, both architecturally and in terms of design, we would make a tyre. It would be a boat less than 10 m long, but top of the range, because we have specialized in this environment" concludes Bertrand.

Installation of a supporting plan on the base plate © Bateaux.com

/

/