A modern way to make electricity in boats

After having worked on the establishment of the Fusion audio equipment brand in France, Alexandre Jardin is now in charge of the development in France of EmpirBus products for the Garmin group. Based on the principle of "Digital Switching" or multiplexing, they use electronic modules to replace traditional electrical components, panels, relays... "It's a modern way of doing electricity. No more need for the row of fuses and the classic electrical panel. Everything is connected to the electronic box, which makes it possible to program and, for example, automatically start the bilge pump if the sensor is in alarm," summarizes the sales representative.

Simplify the work of the shipyard

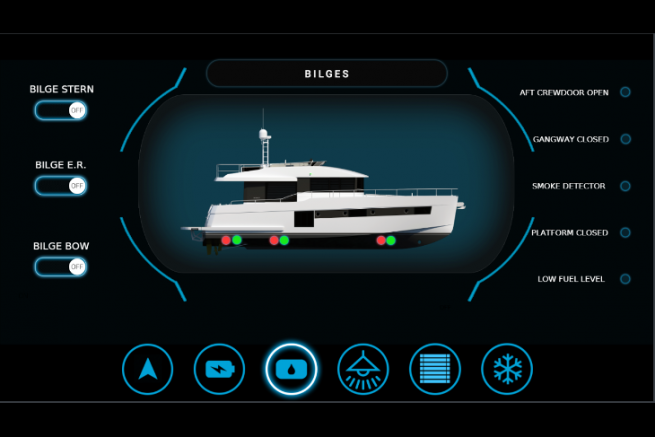

Alexandre Jardin emphasizes two interests in EmpirBus technology, the least known of which is the industrial gain for the boat builder. "For the customer, it simplifies the use of the boat, with a graphic interface on a panel, more pleasant than an electrical panel, but EmpirBus is more than just beautiful screens! It simplifies wiring and installation, saving weight and time. There is only one wire to connect to the box instead of a large bundle. We also gain in waterproofness, the modules being IP67. Even though it's hard to weigh because only the jobsite knows how to install it, I'm convinced that when you take everything into account, the purchase of the material and the installation time, you're equal to or less expensive than a conventional system."

When asked about the risk of failure due to electronics, the EmpirBus manager justifies the robustness of his technology. "It has been standard in the automobile for 20 years. It is even used for the gas pedal and the level of safety in the automobile is very high. If there is a problem with a module, there is a high level of redundancy. The information is redistributed by wifi, which allows intervention via a smartphone. This is also possible directly on a module. And if one of them is changed, there is no need to reload the software," explains Alexandre Jardin.

The French nautical industry is late, but ready to change

After six months of presentations to French yacht builders, the sales representative perceives a strong appetite for its EmpirBus solution. However, the process is going to be long, due to the work habits to be changed. "The shipyards are very interested. We have made the first deliveries and installations. But it's a changeover that takes time, because the entire electrical installation has to be redefined. It's more about new models or one-offs. In the future, this will be of interest to construction sites and a network of EmpirBus experts, an electronics or electric motorization specialist for example, than a conventional electrician, with the ability to program and communicate the equipment."

The example of other neighboring countries makes Alexandre Jardin optimistic. "There are already 50,000 boats in the world equipped with EmpirBus. Italy, for example, is very advanced. It is commonplace in shipyards such as Ferretti or Cranchi," he concludes.

/

/