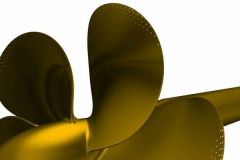

A 3D propeller approved by Bureau Veritas

A consortium has been created between the Dutch shipyard Damen, RAMLAB, the design office Promarin, the software publisher Autodesk and the classification society Bureau Veritas. All these entities will collaborate together on the WAAMpeller project, a 3D printing propeller, approved by Bureau Veritas.

An additive bronze construction

Designed for a tugboat, the propeller will measure 1300 mm in diameter and will weigh 180 kg. Its manufacture, made by RAMLAB in Rotterdam, will use the technique known as WAAM for Wire Arc Additive Manufacturing, an additive printing system using the electric arc.

More design flexibility

The idea for the WAAMpeller project came from 3 students from Delft University, working in the R&D department of the Damen site. The interest for the shipyard is to be able to develop new shapes, while ensuring the good mechanical resistance of the propellers. Don Hoogendoorn, research engineer at Damen, sees opportunities for ecological gain. "Our goal is to build more efficient, profitable and environmentally friendly boats. The WAAMpeller project contributes to this objective because it not only marks a step forward in 3D printing, but also has the potential to bring significant results in optimizing the design of future vessels. 3D printing technology provides an excellent opportunity to improve boat structure, both in terms of performance and fuel consumption."

The first propeller, to be printed in the summer of 2017, will be tested in the fall with a comprehensive and demanding program including bollard pull and crash tests.