3 shells in 1 infusion

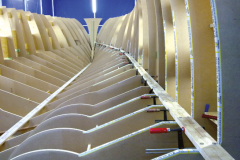

As we mentioned in April, Neel Trimarans is changing its production mode with the arrival of its new multihull model. While the Neel 45 and Neel 65 are assembled from 3 separate hulls, beams and a bridge, the new Neel 51 trimaran is built from a more limited number of elements. The rochelais shipyard produces a unique piece integrating the central hull as well as the two inner wings and half-shells of the floats. The outer half-shells are then brought back.

A technical challenge

According to Olivier Caris, Marketing Director of Neel Trimarans,"the largest cruise trimaran benefiting from this technology, with 160 m² of composite infused at one time The challenge of the operation is obviously in the good diffusion of the resin with a complex geometry. The fine water inlets of the central hull are particularly sensitive in a female mould.

Infusion of the central part of the Neel 51

Increased productivity and a better price

By limiting assembly, Neel Trimarans aims to save substantial time and improve finishing quality. The result for the site is a significant improvement in productivity, reflected in the price of the Neel 51. This one is proposed from 587 000 €, a price close to the competing catamarans of comparable size.

Commercial success

The positioning of the product is a priori successful. Indeed, the yard announces to have already sold 7 Neel 51 on plans. Enough to occupy the workshops of the rochelais building site for several months...